|

JSN is a Shanghai based company founded in 2002 by the current CEO, Jason.

In 2008 the factory relocated to these brand new purpose built premises with integrated offices and

manufacturing on one site of 250,000sq ft, in the new BaoShan Industrial Zone.

The facility is accredited by BSI to ISO 9001: 2000 and specialises in both urea and plastic injection moulding,

along with the manufacture of all the components made from various metals, used in the construction of electrical accessories.

|

JSN management comprises a well qualified and experienced team, who utilise

their collective skills to ensure that quality and reliability are consistently high.

Under the direction of this capable team the business continues to grow in an

orderly and structured way.

A factory turnover of US$12M was achieved in 2012. The present factory

workforce is just 200 people, leaving massive room for expansion.

|

|

|

|

|

|

The in-house test laboratory is

fully equipped with compliant

test equipment.

|

The inhouse design team are

continually refining, updating

and developing the product range.

|

|

|

|

The factory site consists of three identical factory buildings each

with two floors providing 5,000M2 (total 15,000M2).

|

|

|

Of this space, some 70% is currently utilised, which means that an increase in

capacity of 30% could be very quickly achieved.

Each factory building has been designed to support another two floors, with the

support pillars ready in place. This enables the easy construction of enough space to

double the floor area within 6 months.

|

|

|

To ensure the high standard of product quality is maintained, factory facilities include a test laboratory equipped with the relevant test equipment, enabling the QA-QC staff to replicate the BS & EN test procedures as carried out in accredited laboratories.

All products are routinely and rigorously tested within this facility to ensure that they match, or exceed the declared standard.

Up to date approval documentation from accredited laboratories is maintained for all products.

The in-house design team are continually refining, updating and developing the product range, to ensure that both market and customer requirements are met in respect of safety, reliability and innovation. Value engineering is also an integral part of the ongoing evaluation process, ensuring that JSN offers cost effective products, without compromise.

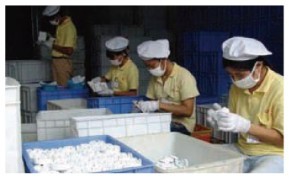

Dedicated QC and inspection staff are dressed in yellow for easy identification. They follow each step in the production line and perform 100% inspection of incoming components and outgoing goods.

|

|

|

|

|

|

|

The Urea Hot Down Press production is constantly

monitored by QC inspectors

(wearing yellow jackets).

|

Production lines are set up with work instructions and

materials are issued accordingly. Care is taken to

ensure that the B.O.M and work instructions are

exactly matched and followed.

|

The injection moulding shop has machines

varying in size from 80 tons, to 260 tons.

These are utilised according to the mould

tool pressure requirement.

|

|

|

|

|

The stamping and pressing shop produces all the metal components required within the products.

Our factory location is ideally placed for procurement of raw materials from the Baoshan

Steel plant, which is adjacent to the Baoshan Industrial Zone.

The engineering department is equipped with all the necessary machine tools to manufacture and

maintain tooling e.g., spark erosion machines, lathes, pillar drills etc.

Multi-impression tools are produced outside by third-party specialist tooling companies.

|

|

|

|

|

|

About JSN

About JSN

About JSN

About JSN